Dassault Systèmes is focused on helping manufacturers in India adopt 3D technology and digitization, to match their production capabilities with global standards. It is also providing the academic world with learning opportunities pertaining to early discovery of 3D to developing more sophisticated industry skills at ITI, ATI, Diploma and Professional Universities.

Dassault Systèmes, the European multinational firm which develops 3D design, 3D digital mock-up, and product lifecycle management (PLM) solutions, has marked several milestones in its journey in the last two years. After the acquisition of Apriso, a leading provider of manufacturing software solutions in 2013, its 3DEXPERIENCE platform embraced global manufacturing operations management. Later, with the acquisition of Accelrys in 2014, Dassault Systèmes introduced a new brand, BIOVIA, dedicated to Virtual Biosphere and Materials, providing global, collaborative product lifecycle experiences to transform scientific innovation. In 2016, it was ranked No. 2 in the Global 100 Index (a rating by by Solactive, the German index provider), which ranks the world’s most sustainable organization.

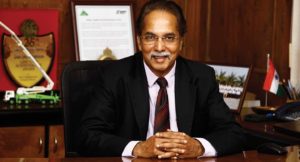

Today, on the lines of Make in India, it is banking on the digitization of manufacturing, to bring companies under Make in India to global standards. As the company’s managing director, Dr. Chandan Chowdhury states, for Make in India to truly succeed, manufacturing processes in India have to reach global standards.

According to a recent research conducted by the council on energy, environment and water (ceew), five key knowledge intensive technologies – biotechnology, nanotechnology, micro and nanoelectronics, photonics, and advanced materials – have the maximum potential to stimulate growth in indian manufacturing sector.

And, they can achieve this by moving away from developing physical product prototypes, which can cause inconsistencies and design inaccuracies at the manufacturing stage, to creating a digital factory which can cut costs, maintain productivity and achieve manufacturing excellence.

A step in this direction for Dassault Systèmes is the adoption of its 3DEXPERIENCE platform in which companies can employ 3D modelling, social collaboration, simulation, and information intelligence technologies to create interactive experiences for their clients or consumers.

In this story, Dr. Chandan takes us deeper into how 3D and digitization can help manufacturers in India achieve global standards, how Dassault Systèmes is driving its adoption in India, and the future of manufacturing in the country.

Talking Make in India

Seeing the initiatives being taken by the Government to eliminate unnecessary laws and regulations, shorten bureaucratic processes, upgrade physical infrastructure to support growth and opening more sectors to foreign direct investment (FDI), it is evident that it wants to be seen as a true business partner instead of a mere ‘permit-issuing authority’.

The need of the hour to enable ‘Make In India’ to become a success story is to harness technology and foster innovation for creating a centre of excellence for manufacturing and services in the identified sectors. According to a recent research conducted by the Council on Energy, Environment and Water (CEEW), five key knowledge intensive technologies – biotechnology, nanotechnology, micro and nanoelectronics, photonics, and advanced materials – have the maximum potential to stimulate growth in Indian manufacturing sector.

Impact of Budget

The budget emphasizes on tax simplification, lower corporate tax, tax holiday for startups and infrastructure spend which is the need of the hour. Last year’s budget was big on intent and 2016 looks like the year of execution.

Programs such as Digital India, Start-Up India and Smart Cities need a strong technological infrastructure that must be supplemented with budgetary support from the government. The Rs. 2.31 lakh crore earmarked for the infrastructure aligns well with the vision to build connected cities via highways and railways. Budget 2016 carries forward the government’s thrust on taking our economy towards global standards of governance by making it more investment-friendly, fairer and transparent.

Dassault’s Plan – enabling digitization of manufacturing

To make the Make In India campaign a success, Indian industries have to establish sync with the global production parameters. While the Indian manufacturing landscape has adopted various methods to achieve operational excellence including going lean, total quality management, automating systems, captive power generation, and alternative energy, recently, digital manufacturing has also emerged as an important tool to cut costs, maintain productivity and achieve manufacturing excellence.

At present, most organizations design digitally but they develop physical product prototypes and then directly proceed to the manufacturing stage. Inconsistencies and design inaccuracies that crop up at the manufacturing stage or post-marketing result in enormous losses. With digitization, industrial processes can easily be connected, tailored and dynamically changed across a network of industrial companies. This strategy, referred to as “Manufacturing as a Service” or MaaS, gives companies the possibility of responding rapidly to changes in demand or in market conditions. Like the ‘Lean’ revolution and other initiatives for continued improvement, this change will take some time. But with a positive mind-set and determination to invest in this future, the digital factory has the potential to offer unprecedented growth for our planet.

At Dassault Systems, the 3DEXPERIENCE platform is the next step after Product Lifecycle Management (PLM). It is a business strategy in which companies employ 3D modelling, social collaboration, simulation, and information intelligence technologies to create interactive experiences for their clients or consumers. The tool simplifies the concept and expands the interpretation of experiences beyond ‘engineering ones’. Some of our key clients who use the platform are Ashok Leyland, Myntra and Arvind Lifestyle.

The Employment Factor

An Ernst & Young Knowledge paper on skill development in India titled ‘Learner first’, indicates that India has gradually evolved as a knowledge-based economy due to the abundance of capable, flexible and qualified human capital. However, there is a need to further develop and empower the human capital to ensure the country’s global competiveness, and the Government intends to achieve this by enrolling 35.9 million students in higher education institutions, with a Gross Enrolment Ratio (GER) of 25.2 per cent by the end of the Twelfth Five Year Plan period (2012-2017).

Simultaneously, in the manufacturing world, Industry 4.0, the vision for the factory of the future is being developed. This means, eventually, the work performed by professionals and skilled labour on the shop floor in a factory of the future will differ significantly from the situation in today’s factories. Consequently, the qualifications and skills of the technicians and skilled labour will differ as well.

Hence, at Dassault, the 3DEXPERIENCE platform and associated technologies is working to provide the academic world with learning opportunities for all ages; from the early discovery of 3D at high schools to developing more sophisticated industry skills at ITI, ATI, Diploma and Professional Universities. The platform will promote the advancement of excellence in all aspects of product, nature and life, which includes skilling people in rural India.